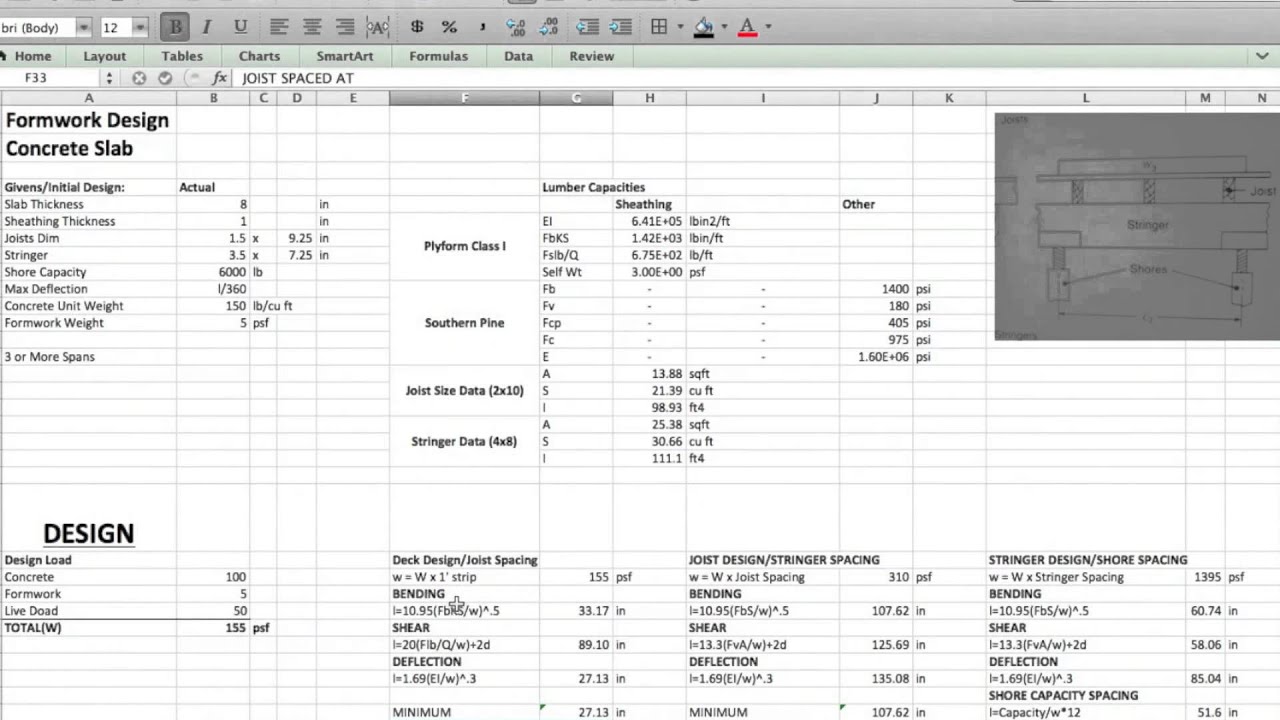

2 Formwork design in Section 3 discusses the concept of designing BONDEK as a formwork Section 4 presents the concept of designing BONDEK as a composite floor slab while Section 5 discusses design of composite slab in fire Design tables for steel framed construction are presented in Section 6 Construction and detailing issues are• Temporary props are equally spaced within each slab span • There are 2 formwork tables for 075mm and 10mm material • Ratio of two adjacent slab spans equal 11, that is I/L=1 • The ratio of the longer slab span (L,) to the shorter slab span (L5) does not exceed 12, that is I 1 / L 5 ≤ 12 22 Speedy erection and dismantling The formwork design and the methods of assembly must be as simple as possible to reduce time spent in erection and dismantling The formwork should be simple to remove without causing damage to the concrete 3

Table Bulk Concrete Slab Beam Formwork Design The Drawing Buy Concrete Slab Formwork Slab Beam Formwork Formwork Product On Alibaba Com

Suspended slab formwork design

Suspended slab formwork design-Formwork—total system of support for freshly placed concrete, including the mold or sheathing that contacts the concrete and all supporting members, hardware, and necessary bracing formwork engineer/contractor—engineer of the formwork system, contractor, or competent person in charge of designated aspects of formwork design and formworkSLAB FORMWORK DESIGN USING GENETIC ALGORITHM Formwork design using GA H ALTABTABAI, AP ALEX and R JAMES Department of Civil Engineering, College of Engineering and Petroleum, University of Kuwait, Safat, Kuwait Abstract A method to design costoptimum slab formwork components is proposed in this paper

Suspended Concrete Floor Slab Formwork System

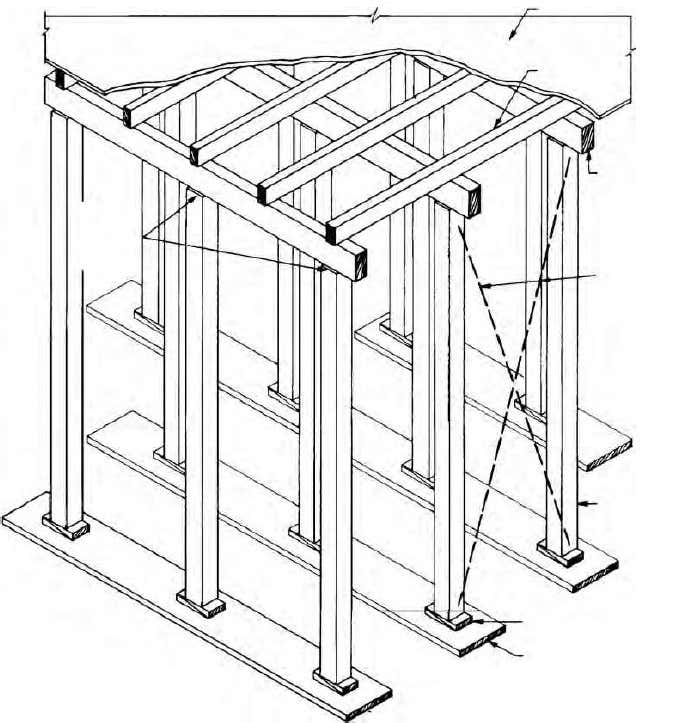

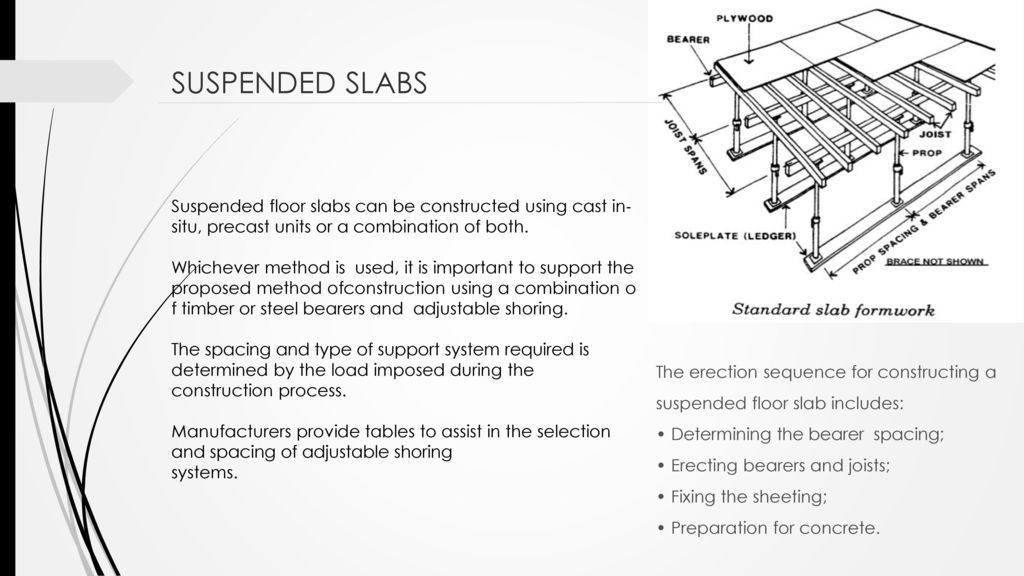

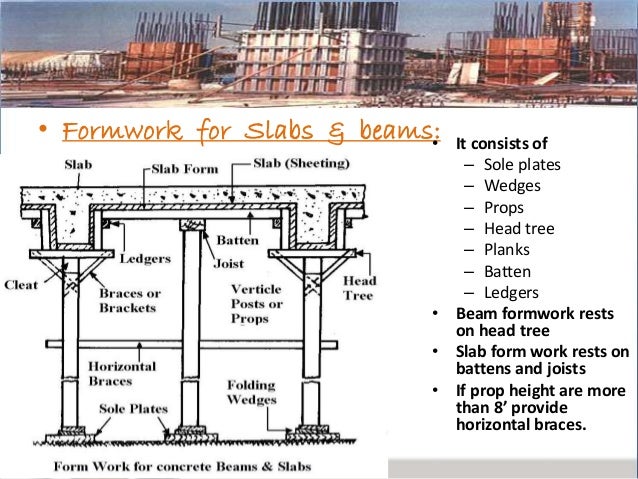

According to every engineering handbook, suspended concrete slabs are defined as flat, tablelike surfaces, which have no direct physical connection to the ground Included in the list of challenges faced by a consulting engineer here, there's the formwork system to create, one that'll support and buttress the concrete slabs as they're installed inside a multistoreyFormwork 21 Work area is cleared and surface prepared for safe erection of formwork for suspended slabs, piers and shutters 22 Formwork is set out to requirements of plans and specifications 23 Formwork is assembled to plans, specifications and class of surface finish, with support system set to correct height level and line 24🕑 Reading time 1 minuteConcrete formworks are subjected to various loads and pressure Concrete formwork loads and pressure calculations are described in this article Formworks or molds are considerably important for building constrictions by holding fresh concrete mixture at place until it get required strength by which the self weight can be sustained Generally, there are

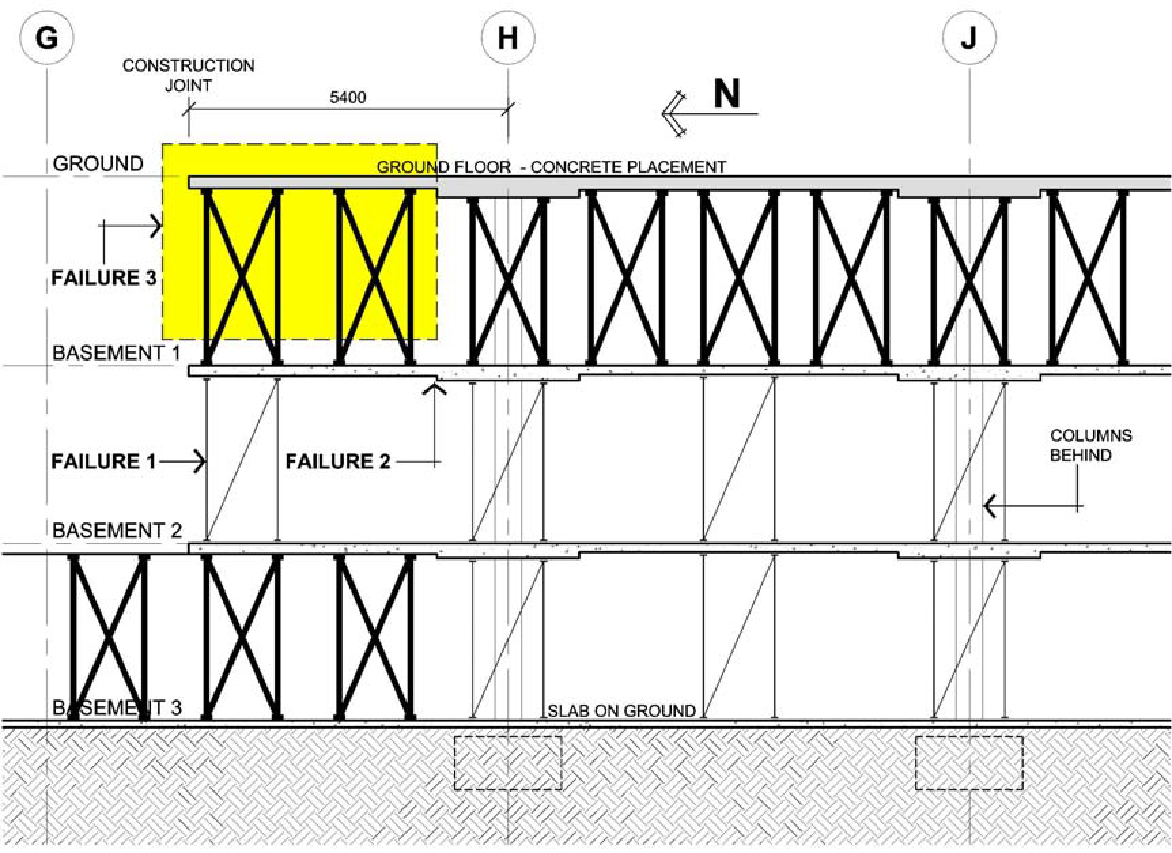

Recommendations for formwork striking and slab backpropping All floors are suspended floors 5 Figure 2 gives location of loads wp, wb1, and wb2 *Backpropping is defined as ECBP slabs struck at 19 hours remain within design limits Traditionally, UK design codes have Temporary Works Engineers will design the best way of back propping a newly poured concrete slabBack propping is used to support a suspended slab while the formwork is being stripped The back propping then remains in place until the slab gains enough strength to support itself It is a vitally important part of the safe and economic construction of insitu concreteFormwork Design Calculations PROPOSED (G2P11R) DUBAI ALNAHDA Next Engineering Consultant Loft Contracting LLC Codes & References British Standards BS 1990 Metal scaffolding BS 24 09 Timber scaffold boards BS 00 Structural use of steelwork in building BS 5973 1993(1) Access and working scaffolds and special scaffold structures in steel

Decking Design and Construction Manual, in conjunction with a BONDEK® steel decking permits installation of suspended BONDEK® sheets continuous over single slab span Formwork deflections limits L/240 (Visual appearance important) Maximum slab spans, mmComposite Mode – end use performance for both strength and serviceability criteriaThe unique suspended concrete floor system Speedfloor is a suspended concrete floor system using a cold formed steel joist as an integral part of the final concrete and steel composite floorThe joist is manufactured in Australia from pregalvanised high strength steel in a one pass rollforming machine giving a high degree of accuracy at a fast production rate

Relation Between Slab Thickness And Dimensions Of Formwork Hussien 19 Structural Concrete Wiley Online Library

Concrete Slab Wikipedia

A Smartslab suspended concrete floor is noncombustible therefore making it ideal for those building in bush fire prone areas TOTAL SERVICE SMARTSLAB provides a total service for the design and construction of suspended slabs Each slab is individually designed and all our work is installed and certified by an experienced SMARTSLAB teamPractical activity for Illawarra Carpentry Students to complete formwork to suspended slabs beams and columnsFRP CONCRETE PTY LTD, established in August 17, is a medium sized company specialising in formwork, reinforcement and concrete installation Our vision is to provide not only a firstclass product but a service that is guaranteed with every project undertaken, all whilst maintaining a high emphasis on safety

Concrete Formwork For Slabs

Structure Suspended Slab Home Building In Vancouver

Weight to the floor slab below, which can exceed that floor slab's design load capacity For this reason, shoring or reshoring is provided over a number of floors to distribute the construction load to several floor levels below Stripping formwork is usually more economical if all the form material is removed at the same time before placing I'm designing a suspended concrete slab over a concrete basement walls for a house garage 24'X24' plan dimension Ideally I would like to avoid beams, but I know locally (Missouri) it has been done with one or two steel W shape beams to support the slabComment by design 2) Formwork 3) Field review of plans 3) Field review of plans and and approval of "as approval of "as constructed" 3) Field approval of constructed" falsework/ falsework/formwork "as constructed" formwork Falsework/formwork 4) "Other" Structures may include a) Rigid Frame Boxes with spans > 16 ft or heights

Concrete Formwork For Slabs

Concrete Formwork For Slabs

Design of the suspended slab using the Stramit Condeck HP ® Composite Slab System requires analysis of three separate functions Formwork Mode – including laying of the decking, propping (if required), concrete pouring and curing, and incidental use during this time such as stacked material loading;The Aluflex system is a high load capacity formwork system for the support and forming of suspended concrete slabs The systems basic components are the Alulight Multiprop, the Aluflex 105 Bracing Frame with primary and secondary beam options The primary beams being secured to the prop heads with steel clips or held in a steel fork headThe formwork designer must be competent in formwork design including documenting a complete bay of suspended floor slab, and modular formwork systems which are often lighter weight and eliminate the need for tasks like repetitive hammering 3 ULY 14 UDE T FMWORK

Construction Suspended Concrete Slab Formwork Systems Shifting Trolley

Slab Formwork Ulma Construction

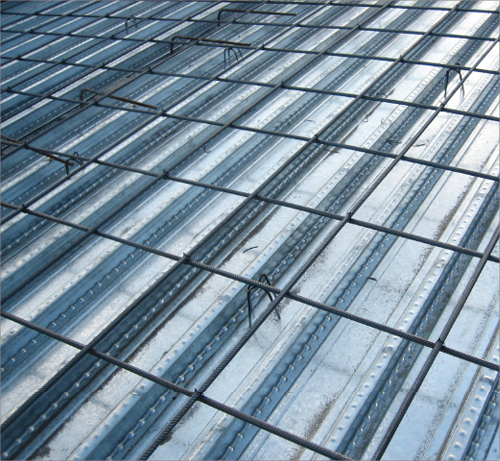

A concrete slab can also be cast insitu It uses formwork into which the wet concrete is poured If the slab is reinforced, then rebars are placed in the correct position within the formwork Concrete is then poured into the formwork For suspended slabs, the formwork will be in the shape of a tray, with supporting slabs underneath AfterConceptual Design Statement Refer to Robert West Drawings no 3095/003/1010, 1011 and 5010 for proposed replacement roof details Actions Permanent Load Roof finishes Permanent Formwork F100 Gauge 12 350mm thick concrete slab (x25) Total permanent load 030 kN/m 2 019 kN/m 2 709 kN/m 2 758 kN/m 2 Services General servicesSuspended Slab Formwork Systems Cassaform offers a full range of slab formwork systems for your next concrete slab From traditional Super Shore formwork frames through to our new aluminium pan system, we can help you find the best system for your next Formwork job

Shoring Support For Concrete Slabs Efco Formwork Solutions

Column Formwork Procedure Formwork For Slabs And Beams

Concrete formwork Square plated screw jacks at bottom, nailed to timber sole plates These under all of the steel support legs and props On the right is the slab formwork for a suspended concrete slab to a multi story building, but this system of concrete formwork could just as easily be used on an owner builder houseTechnical Design Manual Detailed information on design principles and configurations for engineers, architects and specifiers Brochure Get a brochure to learn more about the advantages of this revolutionary suspended slab formwork Based on the formwork design props (supports) are fixed at the beam bottom The spacing of the support shall be as per the formwork design approved by the engineer Once the beam reinforcements are fixed, slab forwork is laid

Design And Calculation Of Formwork Requirement Of Slabs Structville

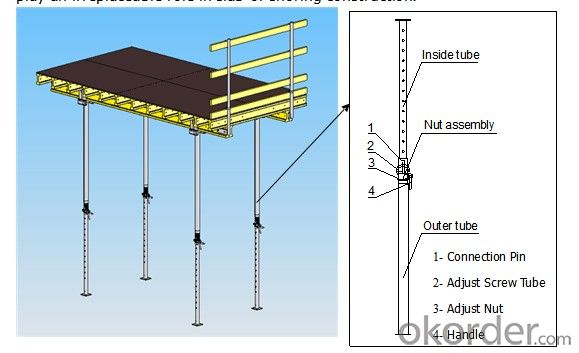

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

The removal of formwork also called as strikeoff or stripping of formwork should be carried out only after the time when concrete has gained sufficient strength, atleast twice the stress to which the concrete may be subjected to when the formworks are removed It is also necessary to ensure the stability of the remaining formwork during formwork removal2 general objectives in formwork building 3 overall planning 4 materials, accessories, and proprietary products 5 loads and pressures 6 shoring and floor loads in multistory structures 7 design of slab, wall, beam, and column forms 8 design of form shores and bracing 9 design tables 10 formwork drawings 11 building and erecting theConcrete Formwork Basher Alamin A Thesis in The Department of fomwork are investigated The present method can be used to design and construct safe and econornical concrete structures, Slab During Construction (Example 1 of Shonng System) 78 Fig 43 2D

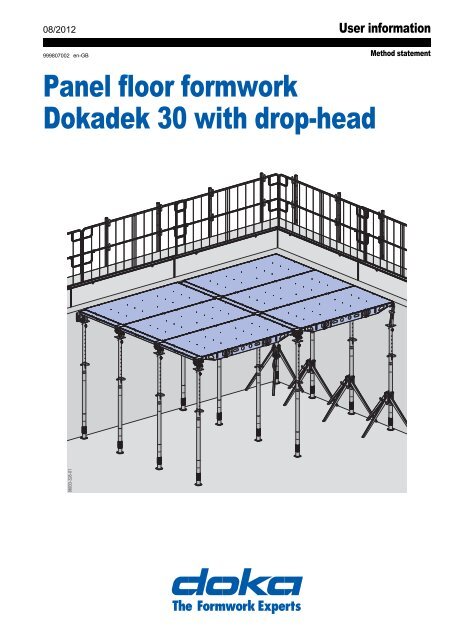

Slab Formwork Dokadek 30 Doka

Skydome Geoplast

Working Together One Structure is a Brisbane based formwork company specialising in Speedfloor, a completely propless lightweight suspended concrete slab system We can also cater for all types of formwork and allinone reo andFormdeck Australia manufacture efficient and durable permanent metal tray formwork reinforcement and ceiling systems which are used for suspended concrete slab construction Formdeck Australia's products have been used on a number of large projects including Hospitals, Shopping Centres, Apartment buildings, carparks and more Slab Design The depth of slab depends on bending moment and deflection criterion For obtaining a modification factor, the percentage of steel for slab can be assumed from 02 to 05% The effective depth d of twoway slabs can also be assumed using cl 241,IS 456 provided short span is

Suspended Concrete Floor Slab Formwork System

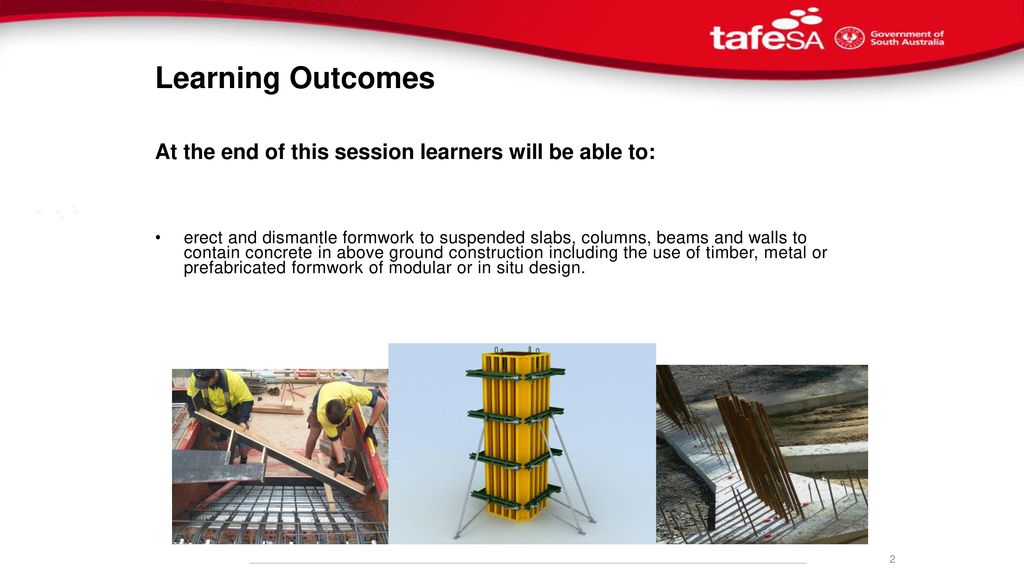

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

30 Formwork design 7 31 Introduction7 32 Recommended deflection limits 7 33 Loads for design 7 34 Use of spanning tables 7 35 BONDEK® maximum slab spans 9 40 Composite slab design 14 41 Introduction 14 42 Design loads 14 421 Strength load combinations 14 422 Serviceability load combinations 14 Cable suspension slab If the span of the slab is very long, then we go for cable suspension slab which is supported on cable such as London Bridge, Howrah bridge etc Generally, in the construction of houses for every 4m, we provide a column whereas in cable suspension slab for every 500m we provide a columnSlabs, but now separated by elastic props, see Figure 2 (b), allowance on the 3m x 3m plan area is considered in the formwork/falsework design, but not in the backpropping calculations Further, the minimum construction operation live load allowance of 05 kN/m² over the entire

Adjustable Prop Vertical Robust Suspended Slab Formwork System Adjustable Prop Manufacturer From China Cccc Fwk International Formwork Corporation

Suspended Slab Formwork Cassaform Construction Systems

Suspended slabs are formed and poured in situ, with either removable formwork or 'lost' nonload bearing formwork, or permanent formwork which forms part of the reinforcement At SNG Engineers we have several years of experience in designing and detailing several different types of concrete frame system 1 Suspended Concrete Floor Slab Formwork SystemSuspended concrete slab formwork moladi Insitu floor Suspended slab formworksystemmoladi designer of a unique patented plastic formwork system has recently design a newSuspended slab formwork system for casting reinforced Suspended concrete slabs Floor slabs to enable the construction of Gibson Building installed a suspended concrete slab formwork system in a residential project in Agnes Water, Queensland Gibson Building trialled a new formwork system supplied by Form Direct in Bundaberg The 'Proshore Formwork System' which was erected by Gibson Building is an innovative formwork system out of the USA

Table Bulk Concrete Slab Beam Formwork Design The Drawing Buy Concrete Slab Formwork Slab Beam Formwork Formwork Product On Alibaba Com

Measurement Of Concrete Formworks For Payment Calculation

A design from Russian NPO22 factory (trademarked as Proster, with model 21 designed to serve as formwork) uses iron "sheets" (with perforations) which, if necessary, can be bent to form a curve The sheetbased formwork with Vshaped rails keeps shape in one direction (vertically) but, before being reinforced with steel beams, can be bent Formwork in construction is the use of support structures and moulds to create structures out of concrete which is poured into the moulds Formwork can be made using moulds out of steel, wood, aluminium and/or prefabricated forms Formwork is an ancillary construction, used as a mould for a structure Into this mould, fresh concrete is placedConcrete slab Suspended slab formwork and rebar in place, ready for concrete pour A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete Steel reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while

5 Things To Look For When Inspecting A Suspended Concrete Slab

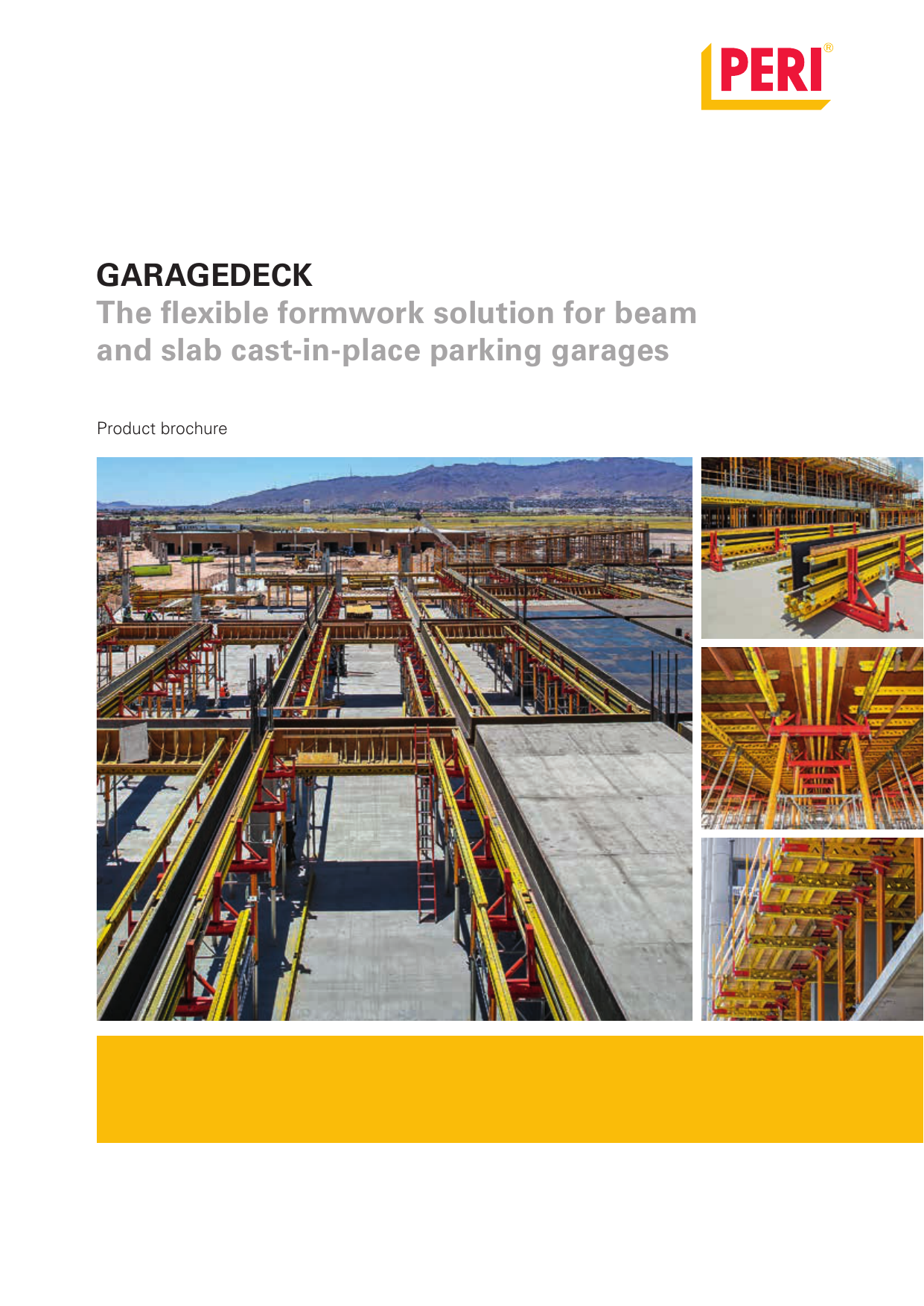

Garagedeck The Flexible Formwork Solution For Beam Peri Usa Manualzz

Suspended Concrete Slab Suspended concrete slab is referred to a cement slab that is not in contact with the ground This type of concrete slab construction requires different concrete slab design from the one we normally see that is cast on the ground The most common application of suspended slab in residential construction is used at garage floor where below the garage floorFORMWORK Health and Safety Construction Safety Association of Ontario 21 Voyager Court South, Etobicoke, Ontario M9W 5M7 Canada (416) Fax (416)

Safety Concrete Formwork For Suspended Slabs China Slab Formwork Aluminum Shutter Made In China Com

Preventing Concrete Formwork Failures In The Commercial Construction Process

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Calculation Of Loads And Pressures On Concrete Formwork Civil Engineering Forum

China Table Formwork With Steel Prop Plywood For Slab Construction China Formwork Formwork System

Flying Table Formwork For Large Area Slab Concrete Construction

1

Flexible Forming System Designed To Reduce Time Cost Of Construction Building Design Construction

Formwork Wikipedia

Safety And Health Lessons Learnt Formwork Incident Office Of The Federal Safety Commissioner

Formwork Bearers

Suspended Slab And Beams Method Of Construction Constructupdate Com

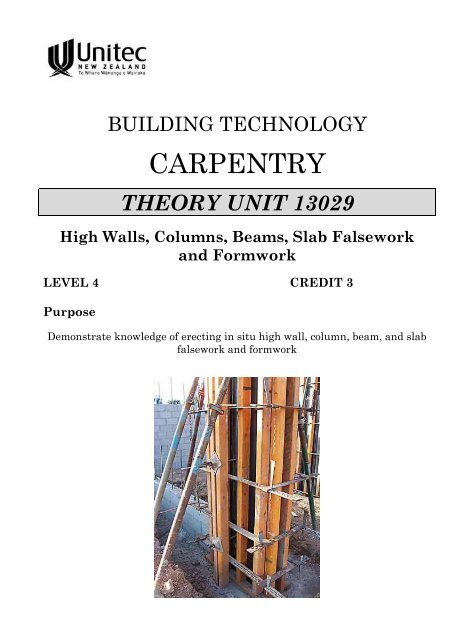

Commercial Formwork Unitec

Floor Formwork Doka

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

Formwork For Decks And Floors Concrete Construction Magazine

Concrete Slab Wikipedia

Suspended Slab Formwork Cassaform Construction Systems

Concrete Floor Slab Construction Process Eplan House

Comflor Non Composite Formwork Composite Floor Deck Tata Steel

Eth Zurich Makes Lightweight Concrete Ceiling Using 3d Sand Printing

Concrete Slab Floors Yourhome

Suspended Concrete Floor Slab Formwork System Pdf

Design And Calculation Of Formwork Requirement Of Slabs Structville

How To Prevent Concrete Formwork From Failing

Concrete Slab Floors Yourhome

2

Back Propping Idh Design

Formdeck Fd300 Durable Permanent Metal Tray Formwork Reinforcement System For Suspended Concrete Slab Construction

Suspended Slab Formwork Cottage Renovation Renovations Outdoor Structures

1

Structure Suspended Slab Home Building In Vancouver

Slab Formwork Design Using Ms Excel Youtube

Formwork To Suspended Slabs Beams And Columns Youtube

Floor Slab An Overview Sciencedirect Topics

Pdf Formwork Design For High Elevated Slab Construction

China Flexible Slab Formwork System For Beam Construction Fl Clam Slab Formwork System

Concrete Formwork Removal Time Specifications And Calculations The Constructor

Formwork Shuttering For Different Structural Members Beams Slabs Etc

Concrete Formwork Removal Time Specifications And Calculations The Constructor

Formwork Ppt Download

Back Propping Idh Design

Slab Formwork

How To Design Slab Formwork With Detailed Calculation Youtube

Suspended Slab

Formwork

Structure Concr Formwork Home Building In Vancouver

This Is Everything Inside A Suspended Slab That A Lot Of People Do Not See We Have A Concrete Beam To The Middle Left Han Storey Homes Ideal Home Construction

Charles Engineering Formwork Design Concrete Shoring

Formwork For Decks And Floors Concrete Construction Magazine

Formwork Wikipedia

Design And Calculation Of Formwork Requirement Of Slabs Structville

Safety Suspended Slab Formwork Shifting Trolley With Hydraulic Power

Safety And Health Lessons Learnt Formwork Incident Office Of The Federal Safety Commissioner

First Floor Concrete Slabs What You Need To Know Eco Built

Why Wouldn T You Use Modular Slab Formwork Systems

Formwork Design Calculation Jobs Ecityworks

Basic Features Of Slab Formwork Or Deck Formwork Bofu Formwork

Oem Permanent Steel Plywood Slab Formwork Scaffolding System With Painting Climbingformworks

Cornerstone Building Civil Engineering Suspended Slab With Removable Formwork Ready For Concrete Pouring Looking At The Example In The Image The Steel Bars Are There To Withstand And Counteract The

Concrete Slab Formwork Design Example Youtube

Understanding The Eskydeck Architecture Design

Slab Formwork Systems On Sales Quality Slab Formwork Systems Supplier

Our Specialized Concrete Services Mcclone Construction

Suspended Concrete Slab Suspended Slab Cement Slab

2

Formwork

Formdeck By Formcraft Pty Ltd Archello

Concrete Formwork For Slabs

Formwork To Suspended Slabs Beams And Columns Youtube

Armourdeck Steel Decking Providing Permanent Formwork Solution For Pacific Fair Project Architecture Design

Doc Concrete Slab Design Dammy Love Academia Edu

Concrete Formwork For Slabs

Panel Floor Formwork Dokadek 30 With Drop Head Doka Lietuva

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Cost Optimization Of A Composite Floor System One Way Waffle Slab And Concrete Slab Formwork Using A Charged System Search Algorithm Sciencedirect

2

2

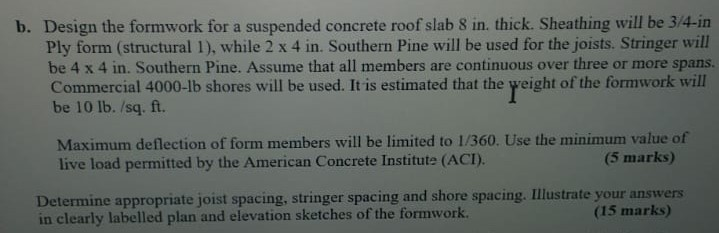

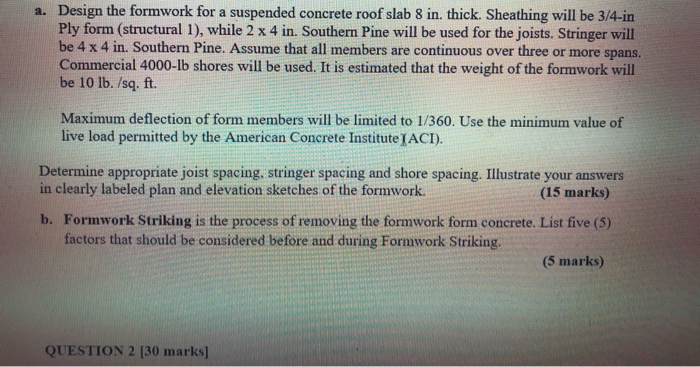

Design The Formwork For A Suspended Concrete Roof Chegg Com

A Design The Formwork For A Suspended Concrete Roof Chegg Com

Large Area Formwork Top 50 By Acrownz Issuu

0 件のコメント:

コメントを投稿